Machine tool bearings

Milling makers - optimal machining quiality even at greater speeds

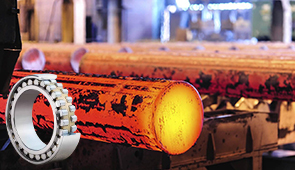

Operating conditions: high level of abrasive contamination, pass through speed, spindle speed, multi-shift or stop/start operations, usage of coolants and lubes.

Applications such as high-speed machining centres and milling devices typically subject bearings to severe operating conditions consisting of abrasive contamination integrated with high feed rates and spindle speeds. In addition, multi-shift or periodic operations can take their toll on the bearings, direct guides and ball screws.

Although we cater for extremely various requirements, our primary objective is to assist you considerably improve the energy effectiveness of your maker tools which will improve efficiency.

GBDS deals services for these applications which have actually been particularly created with your requirements in mind. GBDS's assessment engineers are proficient contact individuals for our clients right from the start. We are continuously broadening our service deal, while considering a great deal of ecological conditions, such as shaft deflections or tilting. Even determining contortion in the bearing environments is possible at any time, both in rotary along with in direct systems. To do this, we compute the bearing load up to the rolling contact with the greatest load. You will get from us the total outcomes for your style paperwork, therefore providing you the security that you require. Our knowledgeable engineers more than happy to deal with you throughout your style phase to assist you choose the very best parts.

Our item portfolio includes direct guides, ball screws and bearings which appropriate for machining different products such as steel, aluminium, titanium and alloys-- in both single-shift and multi-shift operations.

Our engineering knowledge and technological proficiency are based upon GBDS's 4 core innovations: tribology, product engineering, analysis innovation and mechatronics. We ensure you high-technology bearings and skilled support throughout the advancement of your device tool.

This supplies us with an incorporated innovation platform that functions as the base for establishing positive services.

That's our promise when you deal with GBDS to discover an innovative bearing option for your application.

In machining applications, the hydraulic drives offer optimum accuracy throughout tool motion, while securing gadgets hold workpieces in location. Whether it is hydraulic controls, power systems, obstructs, valves, cylinders, pumps, motors, or filters that you are trying to find, we have the service you require in our varied variety of items.

In addition to our items, we provide an useful, appropriate services-- such as Application Analysis considering your specific specifications such as speeds, spindle size and external loads, permitting GBDS to determine the output specifications such as lube life, spindle tightness and more to assist you accomplish optimal performance, accuracy and maker performance.

Our series of bearings uses you the very best worth for loan. From acquiring to upkeep, we optimise expenses without ever stinting quality. The dependability of our bearings makes sure a decrease in your upkeep expenses.

Cutting - improved energy performance for your maker tools

Turning, milling and grinding are standard cutting innovations in the maker tool market. A vast array of principles and device tool types are required to produce mechanical elements. These particular requirements likewise use to the elements utilized in the maker tools.

Nut cooling in ball screws for a lower operating temperature level

There are numerous sound arguments for keeping a steady temperature level listed below 40 ° C in ball screws to ensure the utmost accuracy. Temperature level increases due to the quick movement of the nut triggering modifications in running habits. It is an aspect which must not be ignored.

Focus on the range of bearings for machine tools

Spindle bearings , Rotary table bearings , angular contact ball bearings , single and double row cylindrical roller bearings , thrust ball bearings , Precision ball screw , Feed spindle bearings , ball screws , slide rails , Linear guidance systems

GBDS's high-precision items stand out by providing unparalleled completing precision, even in these conditions. They make it possible for ultra-high speeds, dependably and peaceful running producing the optimal machining quality and cost-effective services.