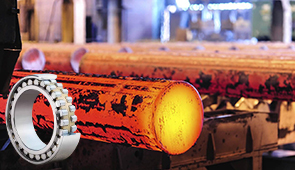

Steel Industry

In response to the need for increased productivity and product quality, We offer bearings that have been specially developed for all the relevant conditions encountered throughout the entire process. from raw material storage yard to the steelmaking, rolling and refining processes, GBDS understands the extreme conditions that rolling mills and casting operations face. Using our bearings and mechanical systems expertise, we deliver bearings and machinery parts tough enough to perform reliably in such harsh environments.

In steel & non-ferrous industries, bearings is unique to steelmaking, with particle contamination, water intrusion and high heat. They have to additionally handle hefty or shock tons, vibration, operational speeds ranging from extremely slow to extremely high, coupled with rapid acceleration and deceleration -this creates a requiring operating atmosphere.

With GBDS's full range of bearing products, from Spherical Roller Bearings for Use in Continous Casting and Cylindrical Roller Beaings with Aligning Rings for Locating Position, reliable Taper Roller Bearings with Aligning Rings for Locating Position, control systems, advanced Long-Life Split Cylindrical Roller Bearing Units technology and power management through to process technology and optimization solutions, we enable our customers' plants to run more efficiently, produce high quality products while increasing a comprehensive range of bearings to help combat these issues, from standard bearings to our own innovatively developed, high-capacity bearings.

GBDS understands the extreme conditions that rolling mills and casting operations face. Using our bearings and mechanical systems expertise, we deliver bearings and machinery parts tough enough to perform reliably in such harsh environments

GBDS have developed sealed spherical roller bearings and thrust Bearings prevent the ingress of contamination and offer optimal service life. we increased the service life, by 4 or 5 times, of the floating bearings used in continuous casting thanks to the axial load capacity of GBDS bearing, four-row tapered roller bearings and spherical roller bearings with self aligning outer ring are also perfectly suited for continuous casting plants.we increased the service life, by 3 times, of a rolling mill bearing by using the four-row tapered roller bearing and Direction Angular Contact Thrust Ball Bearing .

Taper roller bearings which are available in various special materials for rolling mills with our Sealed-Clean technology.GBDS 's surface treatment makes it possible to extend the life of the rolling mill bearings even further.

Bearings for sinter machines, converters, chain conveyors, levellers and many more.

GBDS offer the sealed four row tapered rolling bearing (Sealed Clean) on to the market. which not only leads to lower costs but also makes it more environmentally friendly. GBDS have continually improved and have been able to measurably increase its load-carrying capacity through newly-developed internal construction and a new sealing system. GBDS‘s various steel specifications are particularly wear and shock resistant due to our special heat and surface treatment technology Sealed-Clean bearings can be supplied in case-hardened and through-hardened steel.

GBDS of Selective bearings allows you to tailor a machinery parts solution for your needs, including Cylindrical Roller Beaings , Taper Roller Bearings , Long-Life Split Cylindrical Roller Bearing Units solutions for radwaste streams in commercial power plants.

GBDS support you ensure the success of your operation and reduce the total cost of ownership of your bearings.