JTEKT's machine tools, best represented by our lathes and machining centers, can indeed be considered the origin of "monozukuri". Our machine tools are featured in countless applications, from car parts to the resin molds of cellphones and there is a diversity of precision rolling bearings for such machine tools. The precision rolling bearings developed by JTEKT earn our customers' trust through operation in spindles, ball screw support units and peripheral devices.

- Related product types:

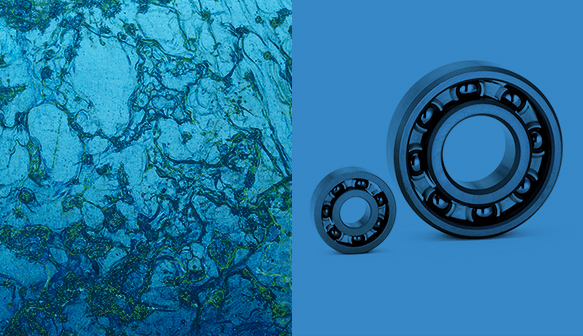

Low temperature rise is sought of bearings supporting a machining center's spindle, in addition to high rigidity and high accuracy in order to suppress the effects of expansion caused by heat generation. Our High Ability Series made from ceramic is adopted for ultra-high speed rotation, so that temperature rise can be lowered by 30 to 50% compared with conventional bearings. The next-generation High-Ability NX Series under development will enable temperature rise to be reduced by around 40% due to optimization of the internal design and cage design.

- Related product types:

A spindle motor is required to be high-speed and high-output in order to achieve highly efficient machining, therefore bearings with high-speed and low-temperature-rise are adopted.

- Related product types:

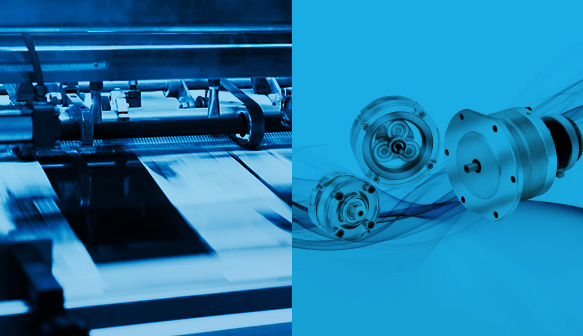

The ball screw is used for the transfer and positioning units of a machining center.

JTEKT supplies highly accurate and highly rigid ball screw support bearings as well as ball screw support units combined with a precision housing that have substantially simplified installation work.

- Related product types:

-

- -

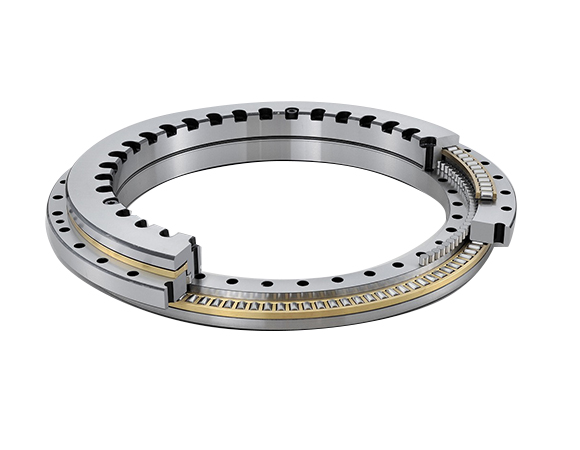

Four-axis control tables such as the index table and rotary table are used in the machining center.

Through highly accurate and rigid table bearings, JTEKT suppresses displacement and runout caused by external forces of the workpiece to a minimum and contributes to improvement of the machining accuracy.

- Related product types:

-

- -

Spindle units incorporating highly rigid, highly accurate and low heat generation type bearings are adopted for the spindle of the lathe with which heavy duty cutting is handled.

- Related product types:

The ball screw is used for transfer and positioning units of the lathe.

JTEKT supplies highly accurate and rigid ball screw support bearings as well as ball screw support units combined with precision-made housing, thus significantly simplifying installation work.

- Related product types:

The tailstock is a section where the free side of a workpiece is fixed. Highly rigid, accurate and low-heat generation bearings are used here in order to maintain a high level of machining accuracy.

Reliable, corrosion-resistant and suitable for use in solutions

A precision reduction gear adopting Koyo bearing technology

A bearing achieving both size reduction and higher capacity (longer life)